Pulished on Apr. 08, 2025

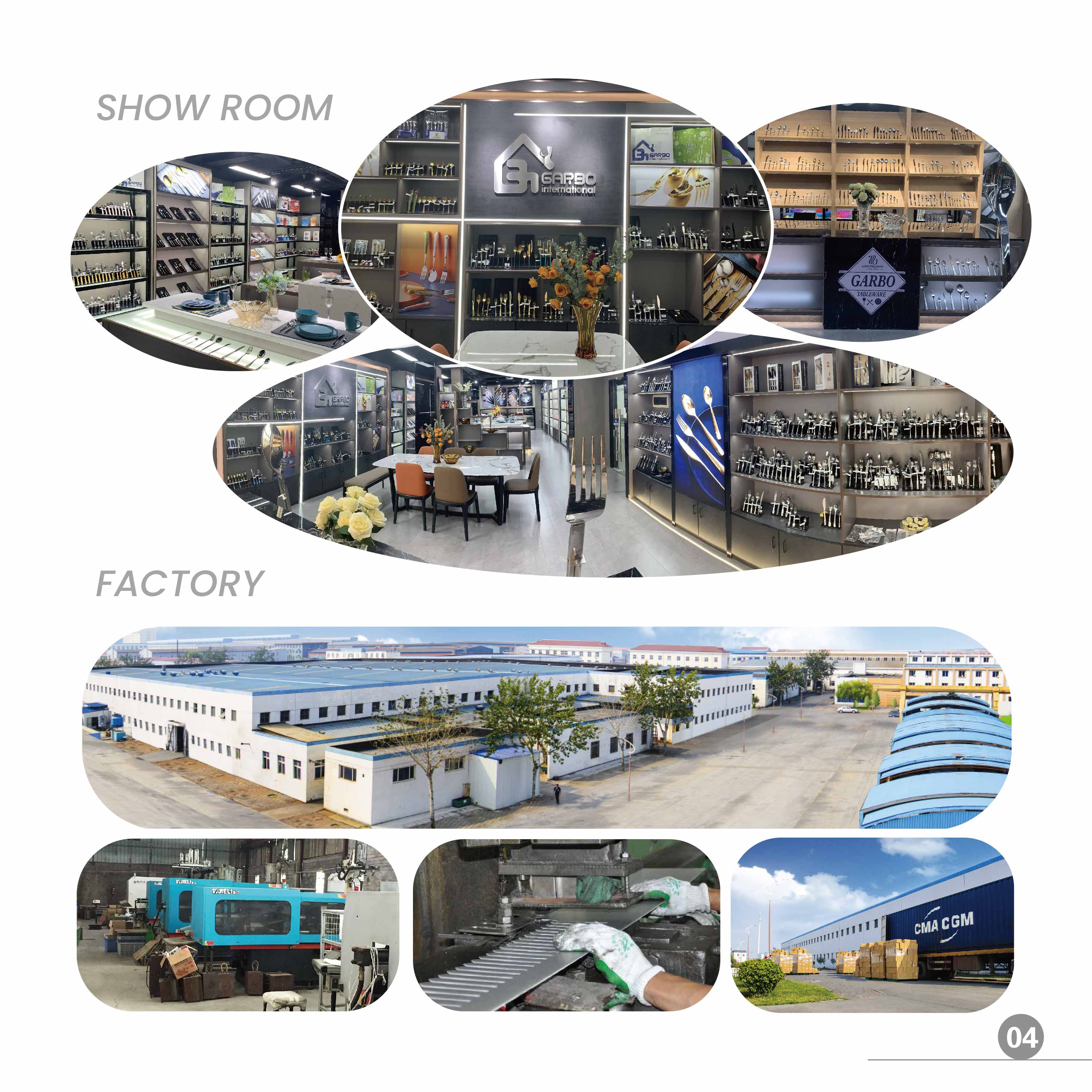

Traders in the cutlery business are most concerned with quality. Because many poor quality knives and forks are easy to rust, deform, fade, and even break. The poor quality of materials used will affect sales and damage brand credibility. We have been making cutlery and cutlery for more than ten years and exported to 165 countries and regions. We know what wholesalers and importers need. A supplier with stable quality, reasonable price and reliable supply is very important. Our production process is mature, the factory area is 22,000 square meters, and the inventory is sufficient, can ship quickly, to help customers seize market opportunities.

We use high quality stainless steel sheets. 18/10 stainless steel contains 18% chromium and 10% nickel, not easy to rust, not easy to corrosion, suitable for the high-end market. 18/8 and 18/0 stainless steels are more affordable and suitable for the mass market. All materials comply with international food safety standards, such as LFGB and FDA certification. Customers use safety, purchase rest assured. Our stainless steel raw materials supply is stable, strict cost control, while ensuring quality, but also can provide a more competitive price. Different types of high-quality stainless steel sheets can meet the needs of different markets.

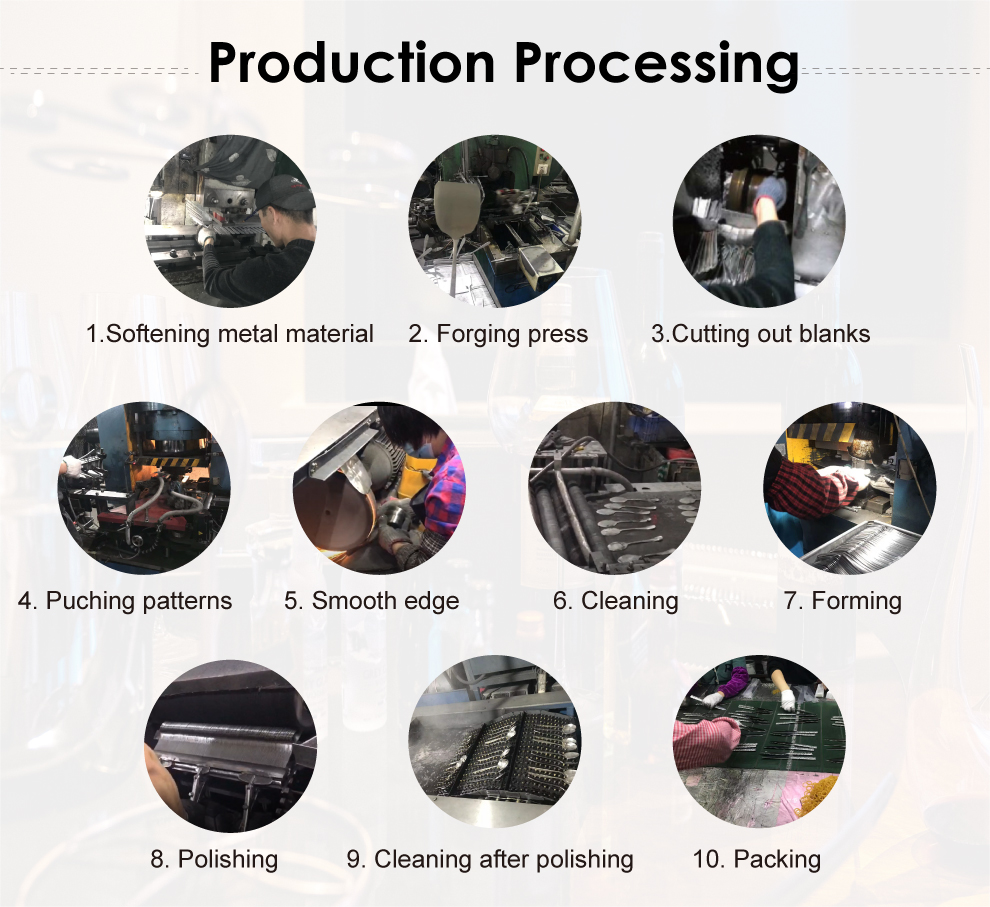

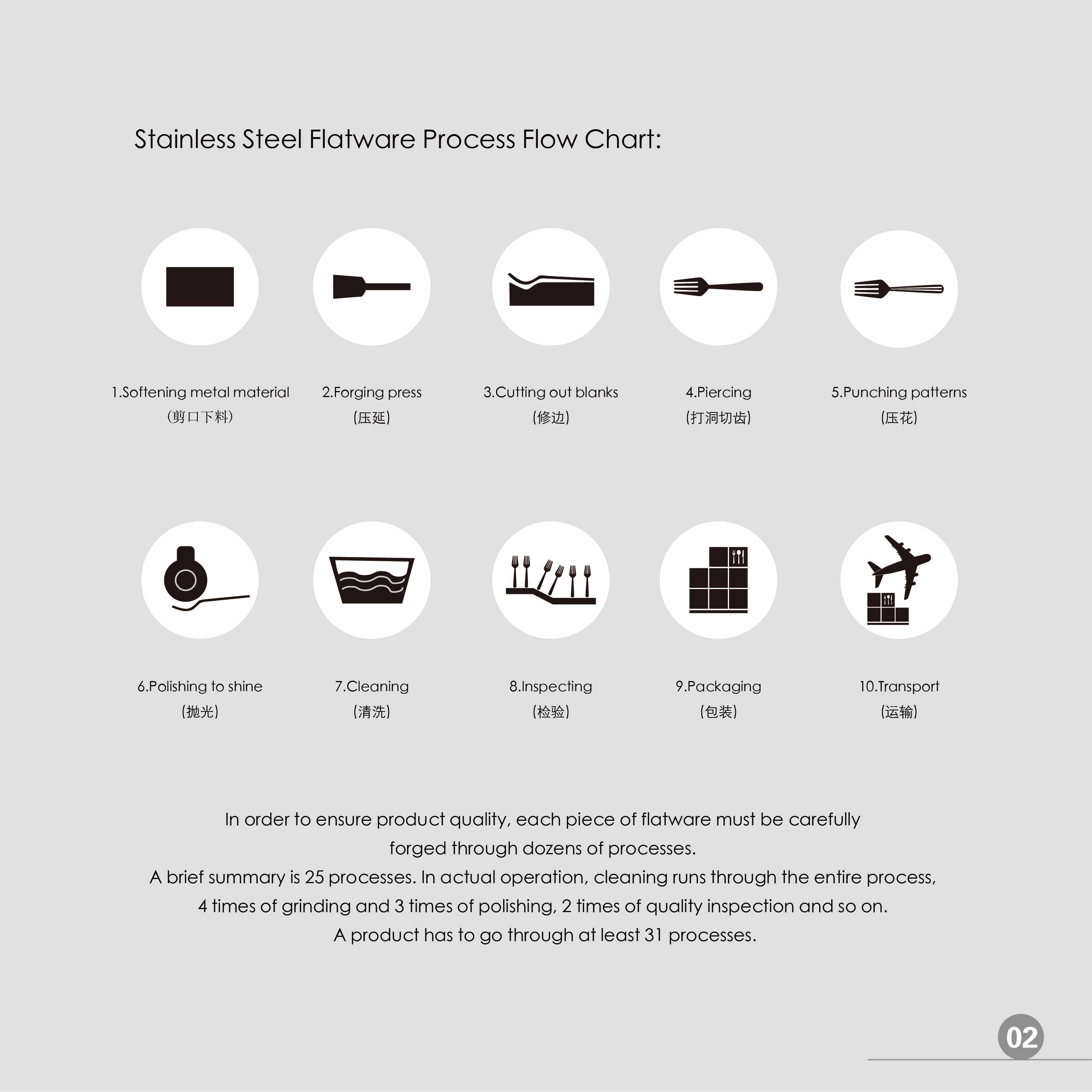

Our factory has 16 production lines, 150 production equipment (transverse drawing machine, laser cutting machine, hydraulic bed, forging machine, imported punch, imported polishing machine, etc.), we use precision equipment stamping, to ensure that each knife and fork shape standard. We use high temperature treatment to make the knife and fork harder and less prone to deformation. We sand it by hand to remove burrs and make it smoother. We use precision machines to sharpen the blades to make them sharper and last longer. Our factories are equipped with automated production lines to reduce manual errors and improve production efficiency. Even for high-volume orders, we can guarantee consistent quality and complete delivery within the specified time.

We have high mirror polish, mirror polish ,hand polish and low mirror polish. We also have PVD coating, which can be made in gold, black, rose gold and other colors. This coating is not easy to scratch, nor easy to fade. Our coatings pass the test and do not flake or fade easily. Customers are more satisfied with longer usage. Our PVD coating process is stable, diverse color styles, can be customized according to market demand, to help customers create differentiated products, improve market competitiveness. Our products can easily pass through the washing machine, which is very convenient for daily cleaning.

Every batch of our products is tested. Salt spray test to check whether knives and forks are rust resistant. The hardness test checks whether the cutlery bends easily. The PVD adhesion test checks whether the coating is strong. We strictly check to ensure that the products received by our customers have no quality problems. Wholesalers and importers have fewer after-sales problems and smoother sales. It also supports 100% quality inspection and third-party testing. Product pass rate is very high, low after-sales rate. This greatly reduces customer return costs and improves end customer satisfaction.

We have a large-scale production capacity, the daily output of 50,000 pieces, about 20HQ/ month, can be stable supply. Because our warehouse has 7,000 square meters, sufficient inventory can support different order quantities, large batch purchase or small batch trial order. We supply directly to the factory, no middlemen, the price is more competitive. Wholesalers and importers can use lower costs to get better profits. Our factory has a stable inventory throughout the year, regular styles can be shipped quickly, customized models can also be completed in a short period of time, to ensure that customers restock on time, not to miss the sales season. The company has 15 designers, a total of more than 200 developers, with 92 patents. Can meet different customized needs.

We have been doing cutlery for more than ten years, exported to Europe, the Middle East, Southeast Asia and other countries. Our customers are walmart, tesco, costco, lidl, target,METRO, etc., for many international brands to produce high-quality stainless steel cutlery spoon products. Today, Garbo has more than 3,000 customers worldwide, and hundreds of B2B tableware purchasing managers have unanimously praised it. The annual export of flatware is RMB 60000000. We insist on making products with stable quality, reliable supply and reasonable price. Wholesalers and importers can cooperate with confidence. In addition, we have a variety of cutlery series, such as stainless steel handle, ceramic handle and wooden handle. And meet a variety of customized plastic handles, plastic handles are PP,PS,ABS material, to meet the needs of different customers. If you need high quality and customized cutlery, please contact us. We can provide you with quotations and samples. Hope to develop with you and make money together.

Looking for Flatware Supplier?

OEM&ODM RequestRequest for Quotation?

Get Factory PriceAny Confusion?

Speak With SalesmanWe deliver the quality and value your flatware needs, on time and within budget.

Contact UsODM&OEM Service

Our flatware is certified by leading retailers including Walmart, Tesco, Costco, Lidl, Target, and METRO, ensuring the highest quality standards.

Experience seamless service from design to export with our one-stop solutions. Our team simplifying your export process and allowing you to focus on growing your business.

Choose from a range of eco-friendly and customized packaging options to suit your specific needs. Our packaging solutions are designed to protect your products while reducing environmental impact.

Our efficient supply chain ensures timely delivery of your custom cutlery, minimizing lead times and keeping your business operations running smoothly.

Comprehensive support & satisfaction guaranteed.