Pulished on Feb. 20, 2025

I believe that many customers want to understand the whole production process of stainless steel tableware. As a professional stainless steel tableware supplier, today we will have a detailed analysis of the whole process of stainless steel tableware production, so that we can more understand the stainless steel tableware industry and the trust in us.

Step 1: Raw material cutting: (refers to the process of raw material cutting through the mold through the machine)

Cut the material according to the approximate shape and size of the product.

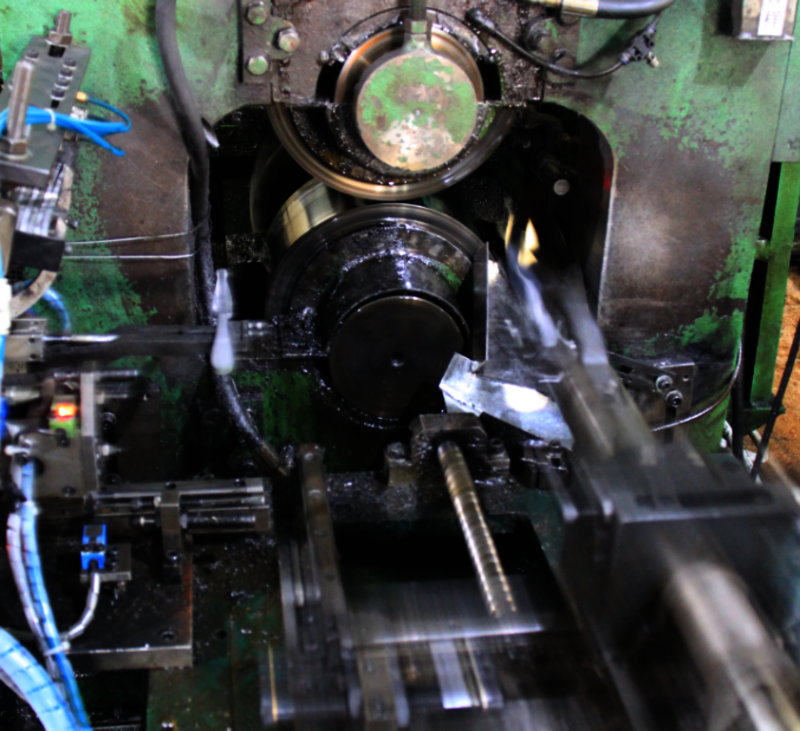

Step 2: Calendering: (refers to the production of the machine after calendering, factory referred to as "transverse pressure")

Calendering: flatten the head of the product, such as spoons, forks, knives, etc., and so on. The thickness is generally 0.8-2mm. Decendering is divided into horizontal extension and vertical extension. Horizontal extension is generally to thin the parts with a slightly wider width of the fork and spoon, such as the spoon head and the fork head; vertical extension is generally a longer product head: such as tools (extend the length of the blade through vertical extension, but the conventional ordinary knife only needs horizontal extension without vertical extension).

Step 3: Trim: (refers to the use of the machine to cut the product out of the specified shape)

In fact, the trim is made of the mold shape (knife, fork and spoon, etc.), and stamping the head of the product with the machine.

Step 4: Pressure: (refers to the product using the machine to squeeze the specified pattern)

After trimming and cleaning, you can distinguish the knife, spoon and fork, but they are still in the shape of the germ plate and the shape of the handle. This step is mainly the shape of the handle, grain, steel seal LOGO and other problems to pay attention to are: because the pattern on the handle is fine, so the mold carving master technology is relatively high.

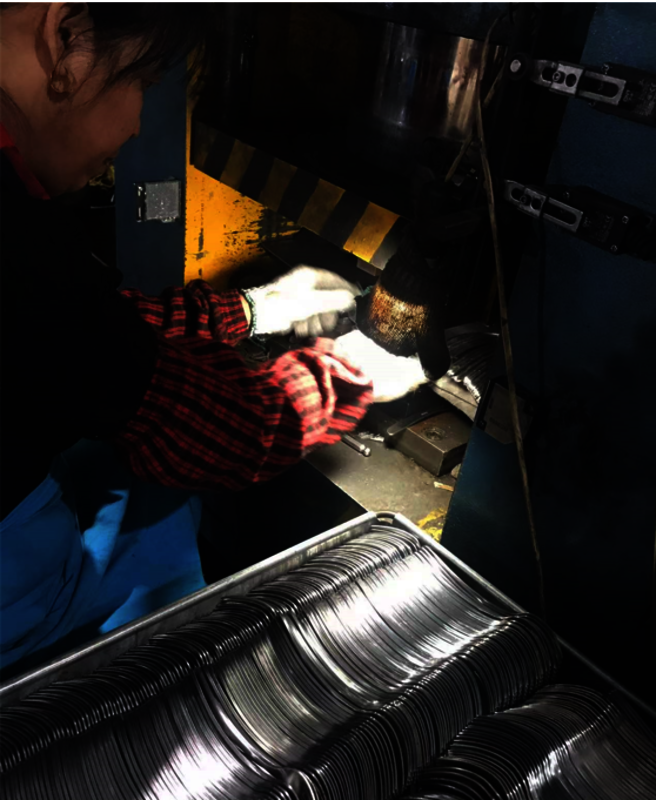

Step 5: Flat edge throwing (after the pressing, polish the surface and side of the material, enter the flat throwing step, and grind the edge first, then flat throwing, and grind the edge also has 5~6 machines for different parts)

The surface of the material itself is not shiny, but should be polished and polished to make the surface of the product bright. Polishing includes surface polishing, and side polishing. Machine polishing or manual polishing with specific grinding materials or polishing materials. Hardware production of many processes need to cooperate with the flat throw.

Step 6: Clean the product surface after flatwashing

Step 7: Pressure type: (refers to the manufacture of the product using hydraulic machine to through the specified shape)

Step 8: Bend throw: (alias cloth wheel throw. Refto the polishing of the whole surface by polishing machine and polishing material)

Step 9: After cleaning: the finished product after the bending will be stored separately with soft cloth to avoid bumping flowers and scratches, but why not be directly packaged? Because after the product is polished and polished, the product will have industrial products such as polishing wax residue, so it needs to use professional dewaxing water with ultrasonic machine for cleaning. Cleaning the assembly line operation.

Step 10: Packing& Quality Control

From raw steel to the finished product, the journey of stainless steel cutlery is a blend of art and science. As a supplier, we take pride in every step of the process, ensuring that our clients receive high-quality, durable, and beautiful cutlery.

If you’re looking for a reliable partner to bring your cutlery ideas to life, we’re here to help. Let’s create something amazing together!

This article not only educates readers about the manufacturing process but also establishes your expertise and reliability as a supplier. It’s engaging, practical, and subtly promotes your services!

Looking for Flatware Supplier?

OEM&ODM RequestRequest for Quotation?

Get Factory PriceAny Confusion?

Speak With SalesmanWe deliver the quality and value your flatware needs, on time and within budget.

Contact UsODM&OEM Service

Our flatware is certified by leading retailers including Walmart, Tesco, Costco, Lidl, Target, and METRO, ensuring the highest quality standards.

Experience seamless service from design to export with our one-stop solutions. Our team simplifying your export process and allowing you to focus on growing your business.

Choose from a range of eco-friendly and customized packaging options to suit your specific needs. Our packaging solutions are designed to protect your products while reducing environmental impact.

Our efficient supply chain ensures timely delivery of your custom cutlery, minimizing lead times and keeping your business operations running smoothly.

Comprehensive support & satisfaction guaranteed.