Pulished on Sep. 06, 2023

When we sit down to enjoy a meal, we often take for granted the tools that make dining a convenient and enjoyable experience. One such tool, often overlooked in its significance, is cutlery. Stainless steel cutlery, in particular, has become a ubiquitous part of our everyday lives. It not only serves a functional purpose but also adds a touch of elegance to our dining experiences. Have you ever wondered how these gleaming utensils are made?

The story of stainless steel cutlery begins with the raw material – stainless steel itself. Stainless steel is a corrosion-resistant alloy of iron, chromium, and other elements. Its unique properties make it the ideal choice for manufacturing cutlery. The process starts with the procurement of high-quality stainless steel sheets. These sheets are carefully inspected for defects and impurities before being used in production.

Once the stainless steel sheets are approved for use, they are cut into the desired shapes for various utensils. From knives to forks and spoons, each type of cutlery requires a specific shape and size. Modern factories often use computer-controlled cutting machines to ensure precision and efficiency in this step.

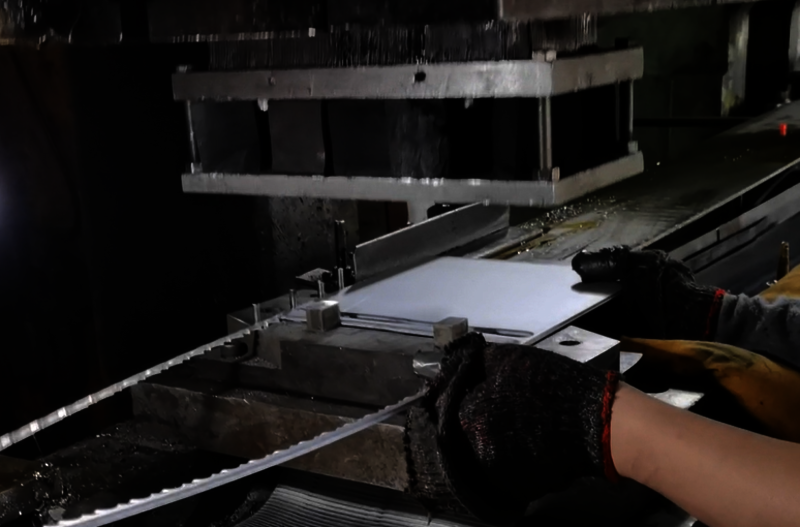

After the initial cutting, the flat pieces of stainless steel are formed into the distinctive shapes of the cutlery pieces. This is done through a process called stamping, where hydraulic presses apply immense pressure to shape the steel. Molds are used to create the intricate patterns and designs seen on the handles and edges of the cutlery.

One of the crucial steps in the production of quality stainless steel cutlery is heat treatment. This process involves heating the cutlery pieces to high temperatures and then rapidly cooling them. Heat treatment helps improve the hardness and durability of the stainless steel, ensuring that the cutlery will remain sharp and resistant to wear and tear over time.

The signature shine of stainless steel cutlery comes from the meticulous polishing process. Automated machines equipped with rotating brushes and polishing compounds buff the cutlery pieces to a brilliant luster. The level of polish can vary, with some cutlery items having a mirror-like finish while others may have a satin finish for a more subdued appearance.

Throughout the manufacturing process, rigorous quality control checks are conducted to ensure that every piece of cutlery meets the highest standards. Inspectors examine the cutlery for any imperfections, such as scratches, dents, or irregularities in the finish. Only those pieces that pass these strict inspections move on to the next stage.

Once the cutlery pieces are complete and have passed all quality checks, they are carefully packaged for distribution. Packaging may vary depending on the market and customer preferences. Some may come in elegant boxes for formal dining settings, while others may be packaged in more functional sets for everyday use.

The production of stainless steel cutlery is not just a mechanical process; it is also an art form that requires skill and precision. The artisans and craftsmen working in these factories play a crucial role in creating cutlery that is not only functional but also beautiful.

The designs on the handles, the choice of materials for handles, and even the balance and weight of the cutlery are all carefully considered to create a harmonious and enjoyable dining experience. Some manufacturers even offer custom designs and engravings to cater to individual preferences and special occasions.

In recent years, there has been a growing awareness of the environmental impact of manufacturing processes. Many stainless steel tableware factories have taken steps to minimize their carbon footprint. Some have adopted more sustainable practices by recycling and reusing materials, reducing water and energy consumption, and implementing eco-friendly packaging solutions.

Additionally, the durability of stainless steel cutlery contributes to its sustainability. Unlike disposable plastic cutlery, stainless steel cutlery can last for generations if properly cared for, reducing the need for constant replacement and disposal.

Looking for Flatware Supplier?

OEM&ODM RequestRequest for Quotation?

Get Factory PriceAny Confusion?

Speak With SalesmanWe deliver the quality and value your flatware needs, on time and within budget.

Contact UsODM&OEM Service

Our flatware is certified by leading retailers including Walmart, Tesco, Costco, Lidl, Target, and METRO, ensuring the highest quality standards.

Experience seamless service from design to export with our one-stop solutions. Our team simplifying your export process and allowing you to focus on growing your business.

Choose from a range of eco-friendly and customized packaging options to suit your specific needs. Our packaging solutions are designed to protect your products while reducing environmental impact.

Our efficient supply chain ensures timely delivery of your custom cutlery, minimizing lead times and keeping your business operations running smoothly.

Comprehensive support & satisfaction guaranteed.