Pulished on Feb. 16, 2023

As we all know, in addition to the original color silver, stainless steel cutlery has many different post-processing processes, including titanium plating (PVD), spray painting, laser, sandblasting. This article mainly introduces the most common PVD, handle spray painting and laser logo.

PVD plating using materials are environmentally friendly, with titanium alloy, can pass food grade test and it is dishwasher safe. The PVD colors include golden, rose golden, black, rainbow-colored.

PVD plating steps are as follows.

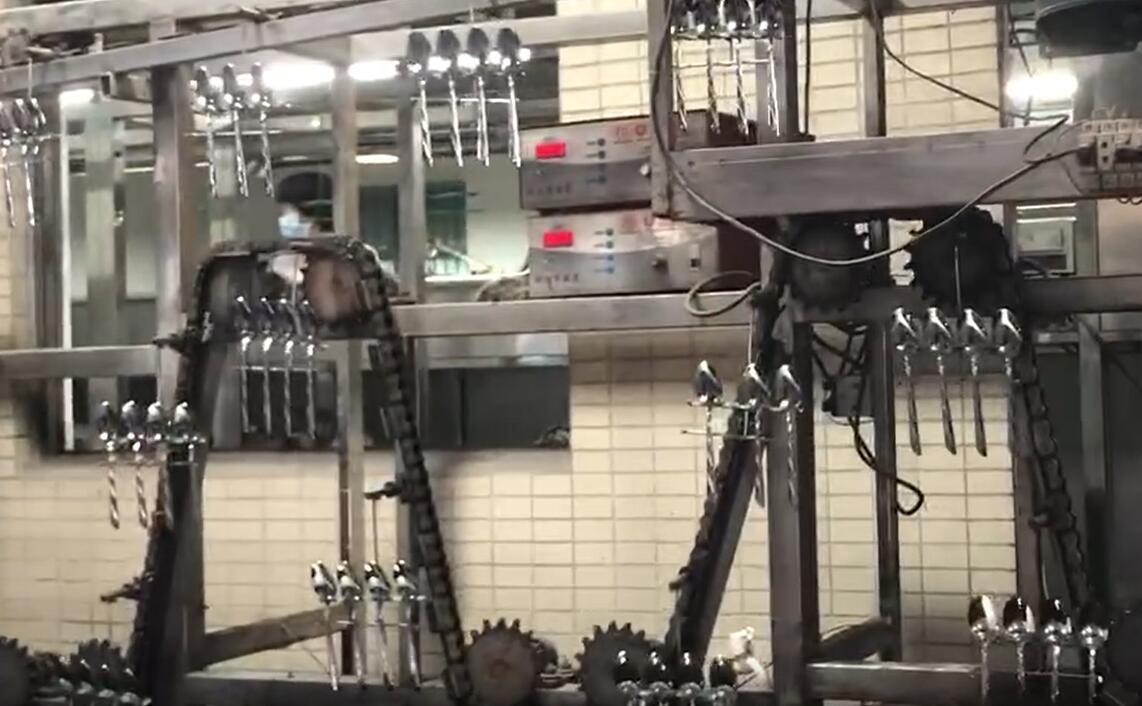

1. First, all the products will be cleaned and dried. (Cleaning (more than 10 meters long cleaning machine - workers towel dry))

2. Then the products are listed one by one to hang on top of the plywood.

3. Then the whole plywood will be sent to the plating apparatus inside the vacuum plating (there are gold plating, illusion, rose gold, etc.), the color is regulated in advance in the machine, through the machine current to adjust the color.

4. After plating, workers will take it out for bagging and packing into boxes.

There are a lot of color options, the surface looks like the effect of vacuum plating, but the surface can touch the more obvious transition bump (looks a little frosted), adhesion is very general, with hard objects can be scratched, once again, the spray paint can not pass the dishwasher test. So it is only suitable for the domestic market and some markets in Southeast Asia that do not require dishwasher testing.

Spray paint steps are as follows.

1. workers first set the product one by one with plastic tape to fix the handle spray paint position.

2. Next, arrange and fix them to the top of the plywood, and then send the plywood to the inside of the spraying machine in a row.

3. Manually rotate the plywood spray paint. After spraying paint and then room temperature drying (is baked dry, to enter the furnace). 4.

4. After drying, workers will first tear off the plastic tape, and then pack into boxes.

Laser only has two colors: black and white, no other colors.

The surface can also be touched with a slight sense of bump, the process is relatively simple, is the use of computer production pattern, the product bag, laser LOGO or pattern through the laser machine directly to the product surface.

Garbo's stainless steel flatware manufacturing process includes all post-processing, and post-processing is a very good option for customized products. If you want a more simple custom style you can also choose to customize a unique logo mold, all ideas just provide us, Garbo can help you achieve!

Looking for Flatware Supplier?

OEM&ODM RequestRequest for Quotation?

Get Factory PriceAny Confusion?

Speak With SalesmanWe deliver the quality and value your flatware needs, on time and within budget.

Contact UsODM&OEM Service

Our flatware is certified by leading retailers including Walmart, Tesco, Costco, Lidl, Target, and METRO, ensuring the highest quality standards.

Experience seamless service from design to export with our one-stop solutions. Our team simplifying your export process and allowing you to focus on growing your business.

Choose from a range of eco-friendly and customized packaging options to suit your specific needs. Our packaging solutions are designed to protect your products while reducing environmental impact.

Our efficient supply chain ensures timely delivery of your custom cutlery, minimizing lead times and keeping your business operations running smoothly.

Comprehensive support & satisfaction guaranteed.